Abstract

The influence of the curly kale addition on selected properties of extruded pellets and expanded snacks.

Development of the extrusion-cooking technology enabled the processing of plant resources with a specific chemical composition and with a large variety of physical characteristics. Extrusion-cooking is based on HTST (High Temperature Short Time) processing with devices called extruders. Proper equipment and processing conditions enable the production of wide variety of products. According to increase in consumer awareness about well-being anf healthy lifestyle some new types of snacks products were developed supplemented with addition of fresh kale leaves. Kale (Brassica oleracea L.) is rich in minerals and vitamins: C, B1, B2, E, K and PP, provitamin A, folic acid and potassium, iron, phosphorus, and easily digestible calcium. Kale consists antioxidants, fiber, and glucosinolates (phytochemicals that reduce the risk of cancer) so supplementation of food products, especially snacks. Potato-based composition was used as control and fresh curly kale was used as nutritionally valuable additive and natural colorant in amount of 10, 20 and 30%. Snack pellets were obtained by the extrusion-cooking and dried pellets were expanded by frying. Selected physical and chemical analyses were performed as well as texture and structure evaluation. Expanded snacks supplemented with fresh kale showed increased nutritional value, improved taste and visual attractivness with intensive green color and various amount of fresh kale affected the structural properties and texture of snacks. These results are part of the research project LIDER/29/0158/L-10/18/NCBR/2019 entitled “Development of a Comprehensive Technolog

Author(s):

Beata Biernacka

Abstract | Full-Text | PDF

Share this

Google scholar citation report

Citations : 393

Journal of Nutraceuticals and Food Science received 393 citations as per google scholar report

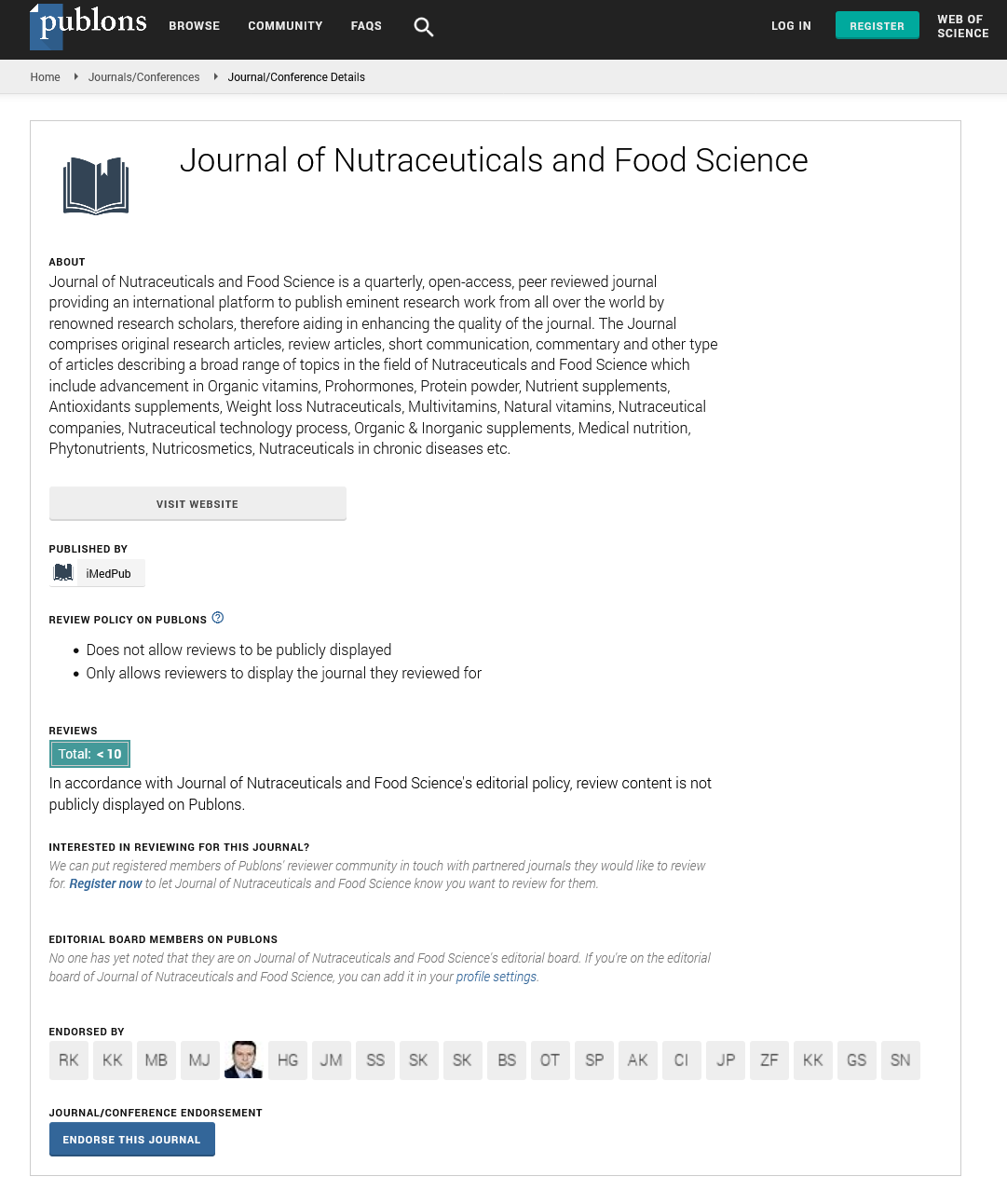

Journal of Nutraceuticals and Food Science peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Publons

- Secret Search Engine Labs

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences