Abstract

The influence of fresh highbush blueberry addition on the extrusion process of snack pellets

In many countries, mainly Europe and the United States, a limited consumption of fresh fruit and vegetables has been observed. The lack of a balanced diet can lead to many civilization diseases such as cardiovascular disease, diabetes, obesity, or colon cancer. In order to minimize this undesirable trend, fresh fruit and vegetables can be added to a variety of meals, including snacks. The aim of this work was to investigate the influence of fresh highbush blueberry addition on the extrusion-cooking process of snack pellets. Extrusion-cooking process was performed using the Polish prototype single screw extrudercooker Zamak Mercator type EXP-45-32. Determination of relevant recipe mixtures based on potato or cereal raw materials and the use of fresh highbush blueberry addition in various amount allowed to obtain high-quality snack pellets. A low level of moisture content of blends and high screw rotational speed allowed to increase the efficiency of the extrusion-cooking process at a relatively high energy consumption during processing. The increased initial moisture content of processed blends and higher percentage of highbush blueberry content in recipies affected the lower consumption of specific mechanical energy during the extrusion-cooking process. These results are part of the research project LIDER/29/0158/L-10/18/NCBR/2019 entitled “Development of a Comprehensive Technology of Obtaining High- Quality Extruded Snacks Based on Minimally Processed Vegetable and Animal Raw Materials”.

Author(s): Marcin Mitrus

Abstract | Full-Text | PDF

Share this

Google scholar citation report

Citations : 393

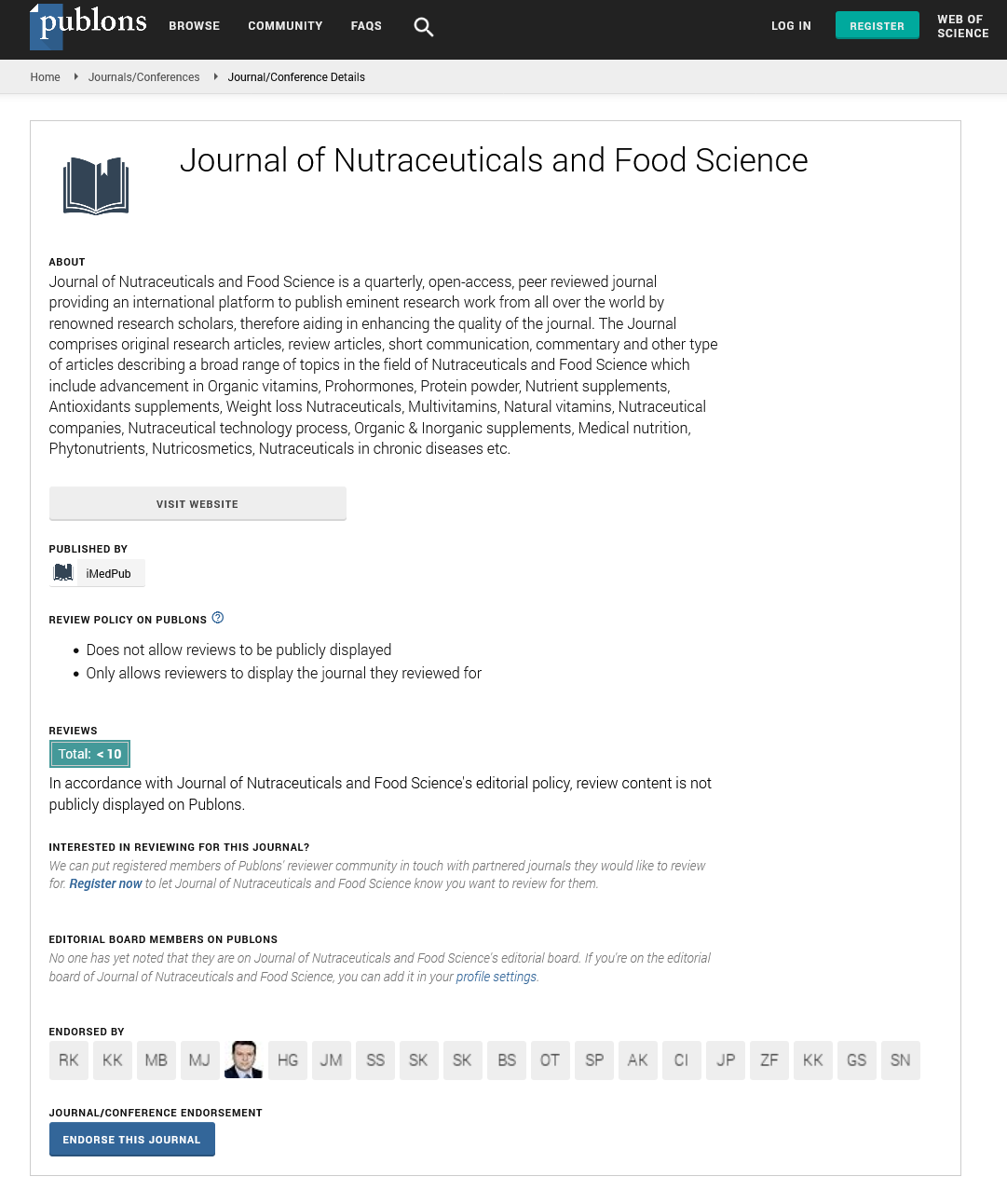

Journal of Nutraceuticals and Food Science received 393 citations as per google scholar report

Journal of Nutraceuticals and Food Science peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Publons

- Secret Search Engine Labs

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences