Abstract

The influence of fresh curly kale addition on the extrusion process of snack pellets

The extrusion-cooking process applications for food products started in the 1950s. Thanks to the development of technological aspects many of producers are interested in design of new devices and equipment to the market, characterized by the possibility to configure the manufacturing process and parameters to obtain appropriate characteristics of the final products. This make it possible to increase the processing potential and to create many new products based on the plant raw materials. The production process of snacks has been significantly progressed in recent years due to possibility of improving nutritional and functional properties of snack products and modern production methods used. Application of extruders has a large impact here, which largely caused the propagation of these types of products among consumers. The energy demands during the production of snack pellets are diverse and depend on the product type. The use of raw materials requiring low energy-consuming processing may affect on the amount of energy and the cost of the final product. Determination of relevant recipe mixtures based on potato or cereal raw materials and the use of fresh kale addition in amount from 10 to 30% allowed to obtain high-quality snack pellets. A low level of moisture content of blends of approx. 32% and high screw rotational speed (100 rpm) allowed to increase the efficiency of the extrusion process at a relatively high energy consumption during processing. The increased initial moisture content of processed blends and higher percentage of kale content in recipies affected the lower consumption of specific mechanical energy during the extrusion-cooking process. These results are part of the research project LIDER/29/0158/L-10/18/NCBR/2019 entitled “Development of a Comprehensive Technology of Obtaining High-Quality Extruded Snacks Based on Minimally Processed Vegetable and Animal Raw Materials”.

Author(s):

Food Science

Abstract | Full-Text | PDF

Share this

Google scholar citation report

Citations : 393

Journal of Nutraceuticals and Food Science received 393 citations as per google scholar report

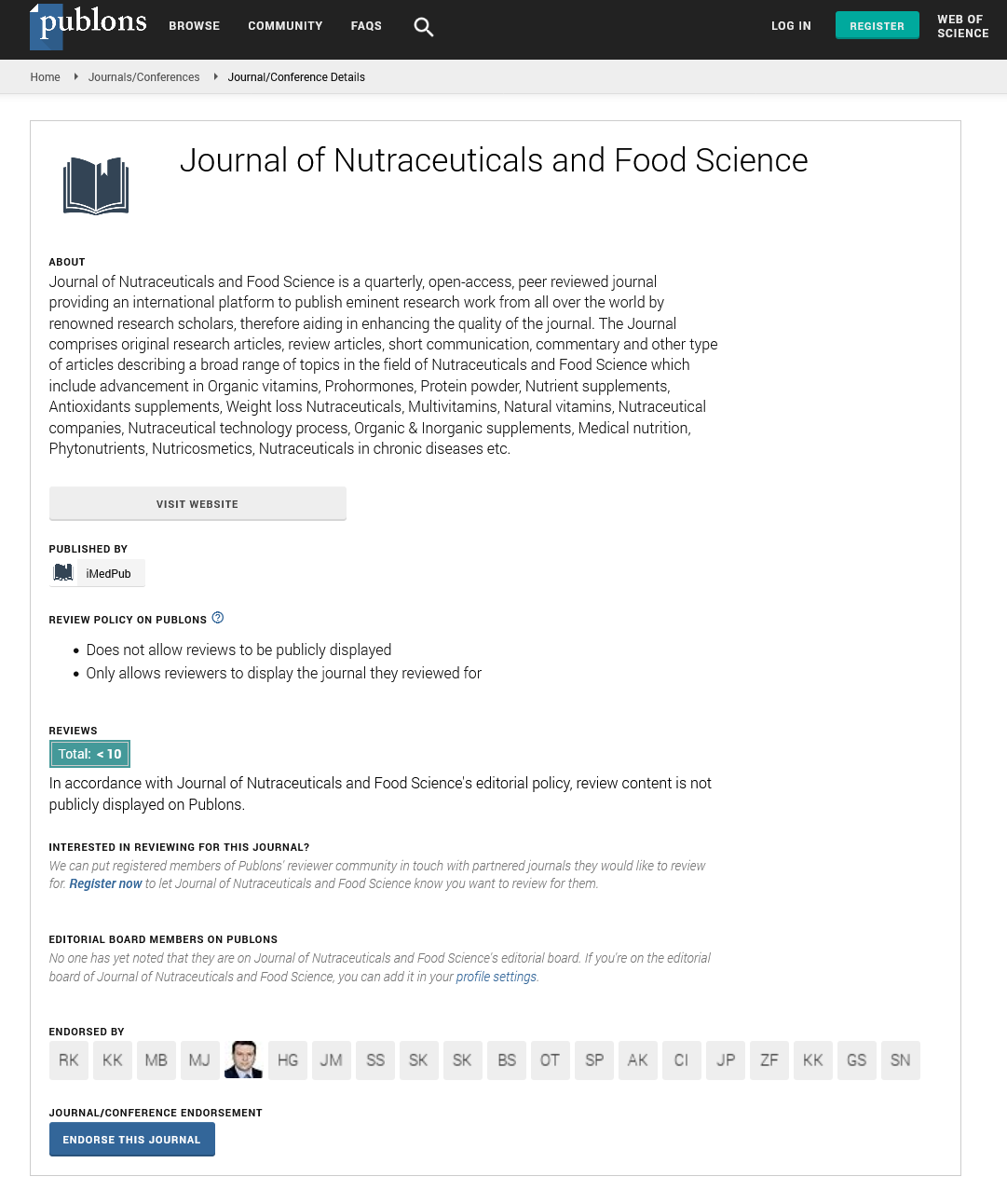

Journal of Nutraceuticals and Food Science peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Publons

- Secret Search Engine Labs

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences