Abstract

Spray Drying: A Modern Method of Food Preservation

The design and critical elements of spray drying, types of spray driers, critical parameters of spray drying, developments in spray drying, and its applications in the pharmaceutical area are all covered in this holistic overview. From the 1870s until the early 1900s, the development of spray drying equipment and processes took place across several decades. With the unexpected requirement to lower the transport weight of groceries and other goods during World War II, spray drying comes of age. By spraying feed into a hot drying medium, this approach allows feed to be transformed from a fluid to a dried particle form. It's a continual drying operation for particle processing. A solution, solution, dispersal, or emulsion can be used as the feed. Depending on the physical and chemical properties of the feed, the dryer design, and the intended final powder attributes, the dried product can be in the type of grains, granules, or agglomerates.

Author(s):

Tabitha Davis

Abstract | PDF

Share this

Google scholar citation report

Citations : 393

Journal of Nutraceuticals and Food Science received 393 citations as per google scholar report

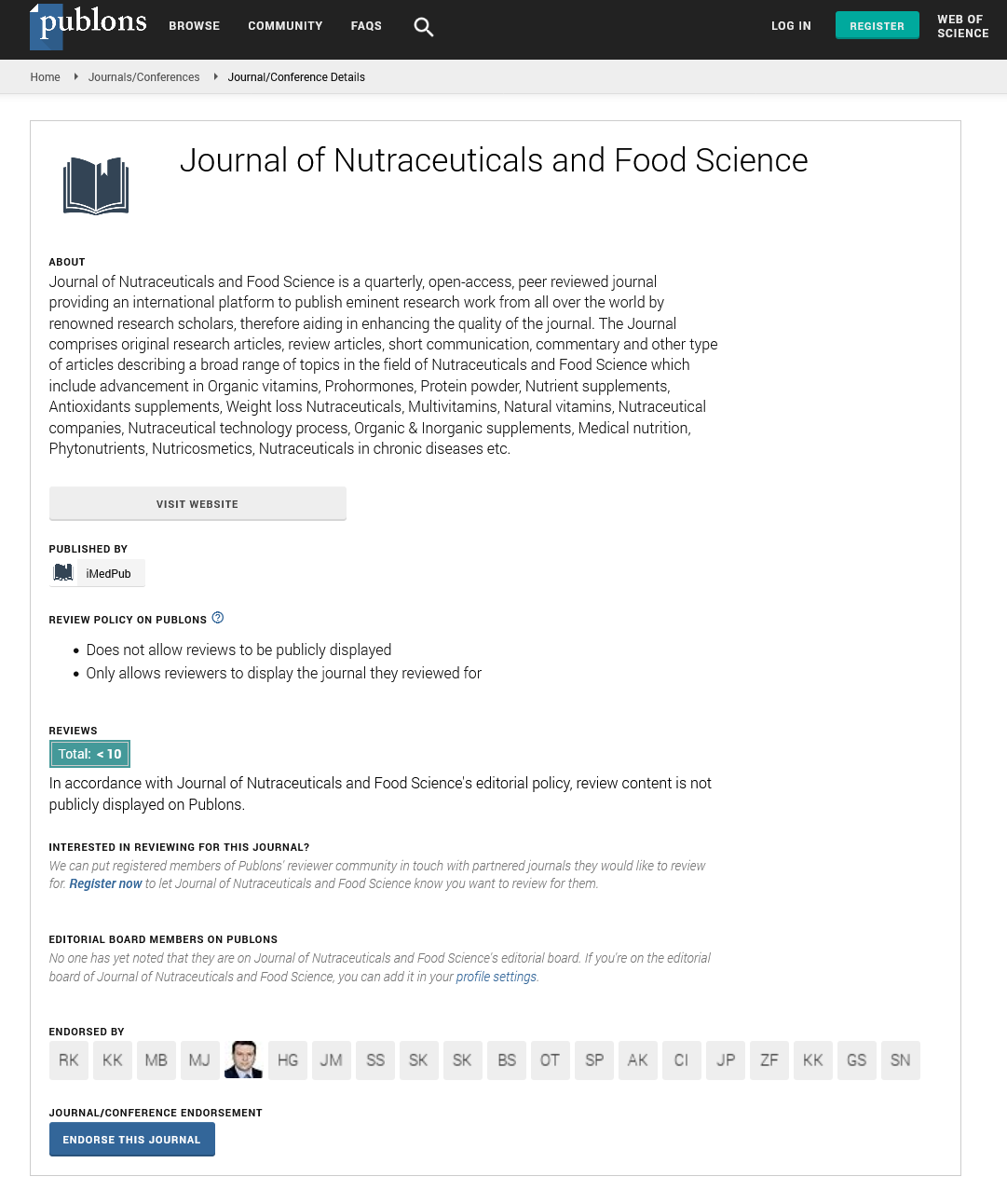

Journal of Nutraceuticals and Food Science peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Publons

- Secret Search Engine Labs

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences