Abstract

Physicochemical Properties of Cassava Processing Residue Flour and Sensory Evaluation of Fufu Prepared from it

This study evaluates the physicochemical properties of the residues obtained from the sieving operation during cassava (Manihot esculenta) gari and starch processing. Residue obtained from the sieving of dried fermented cassava pulp during gari production and extraction of starch, were dried on a mounted platform in an open space before processing into flour. Commercial wheat flour was used as a standard. Physiochemical properties of each flour samples were investigated using standard methods. Results obtained shows significant differences (p<0.05) in the parameters investigated. Cassava gari residue flour sample ranked the lowest in moisture (6.371%). The percentage fat in; cassava gari was found to be 0.057%, cassava starch 0.031%, wheat 3.331%. Ash ranges from 1.786% (cassava starch) to 1.3015% (Wheat). Crude fibre from 2.701% (wheat) to 4.383% (cassava gari) while dry matter was from 93.630% (cassava gari) to 81.680% (wheat). Oil absorbing capacity ranked the highest in cassava starch residue flour (1.745), while in water absorption capacity cassava gari residue flour ranked the highest (1.995). Swelling index ranged from 1.429 (cassava gari) to 1.505 (wheat). The lowest in bulk density and pH was cassava starch flour (0.556, 5.36), while gelation temperatures were 66.5°, 64°, 60.15°C in cassava gari, cassava starch and wheat flour samples respectively. Eight (8) sets of fufu samples were prepared using the residues flour, coded and subjected to sensory evaluation using a twentymember panel. The panellists were instructed to evaluate the coded fufu samples for Texture, Mouldability, Elasticity, Smoothness, Appearance, Thickness and General acceptability. A nine (9) point hedonic scale was used, results obtained were statically analysed. The results show that there were significant differences between the different methods of preparation.

Author(s):

Ohuoba AN, Ukpabi UJ, Kukwa RE

Abstract | Full-Text | PDF

Share this

Google scholar citation report

Citations : 393

Journal of Nutraceuticals and Food Science received 393 citations as per google scholar report

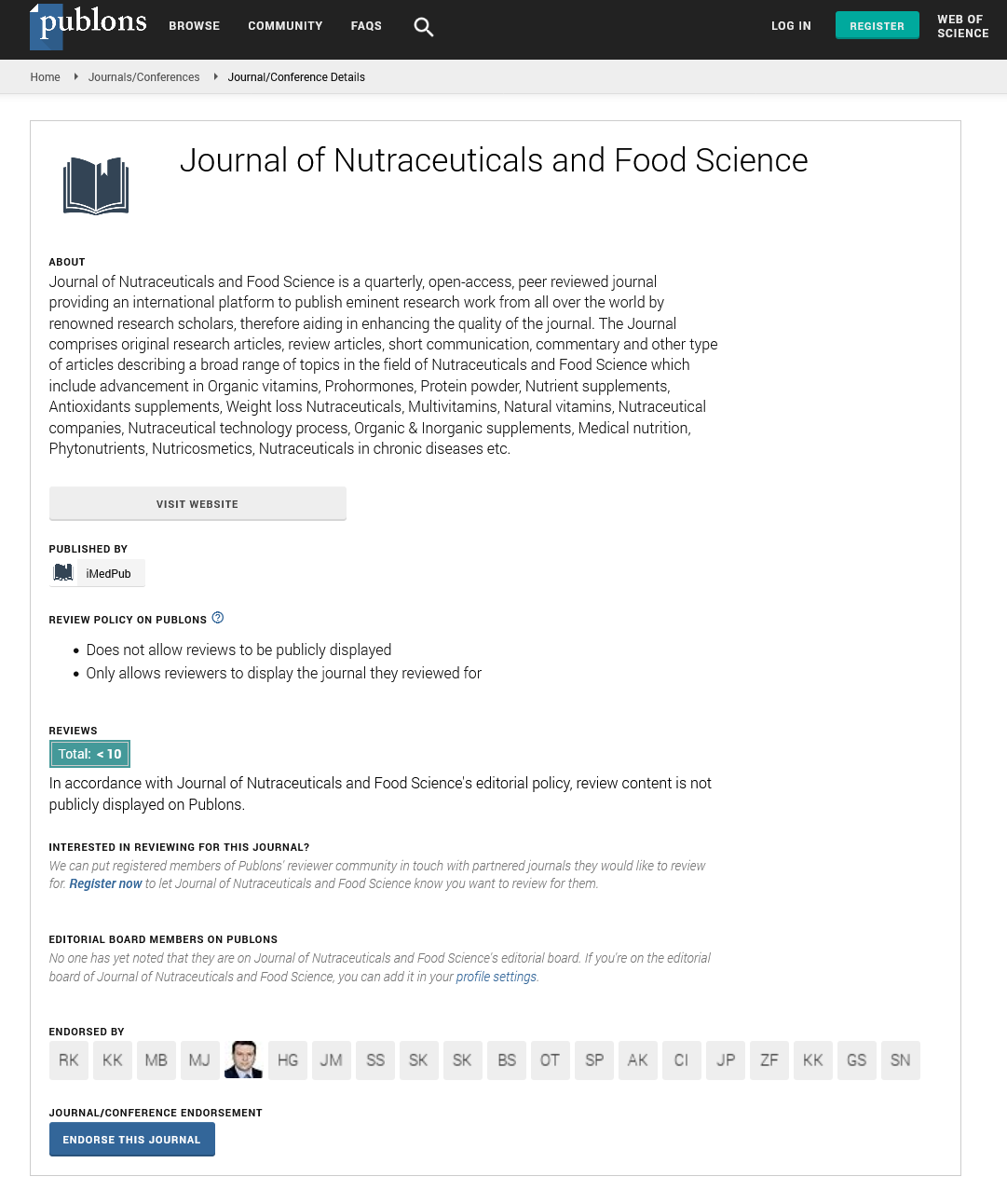

Journal of Nutraceuticals and Food Science peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Publons

- Secret Search Engine Labs

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences