Abstract

Organic Coatings for Food

Between the underlying metal and the corrosive environment, organic coatings act as corrosion barriers. They help constructions last longer by providing weather, humidity, abrasion, chemical resistance, toughness, and a pleasing look. The mechanical properties of the coating system, the kind and concentration of suspended inhibitors, pretreatment of the metal surface, adherence of the coating to the underlying metal base, and other additives that limit substrate corrosion all affect the efficiency of organic coatings. Solvent, resin (binding), pigment, filler, and additives are common ingredients in coating formulations. They provide a continuous, homogenous covering that inhibits cracking and structure disintegration during stress, water permeability, and physical ageing when applied to the underlying metal. To justify the cost, protective coatings should have low permeability, good corrosion stability, and a long-term look.

Author(s):

Rebecca Wilson

Abstract | PDF

Share this

Google scholar citation report

Citations : 393

Journal of Nutraceuticals and Food Science received 393 citations as per google scholar report

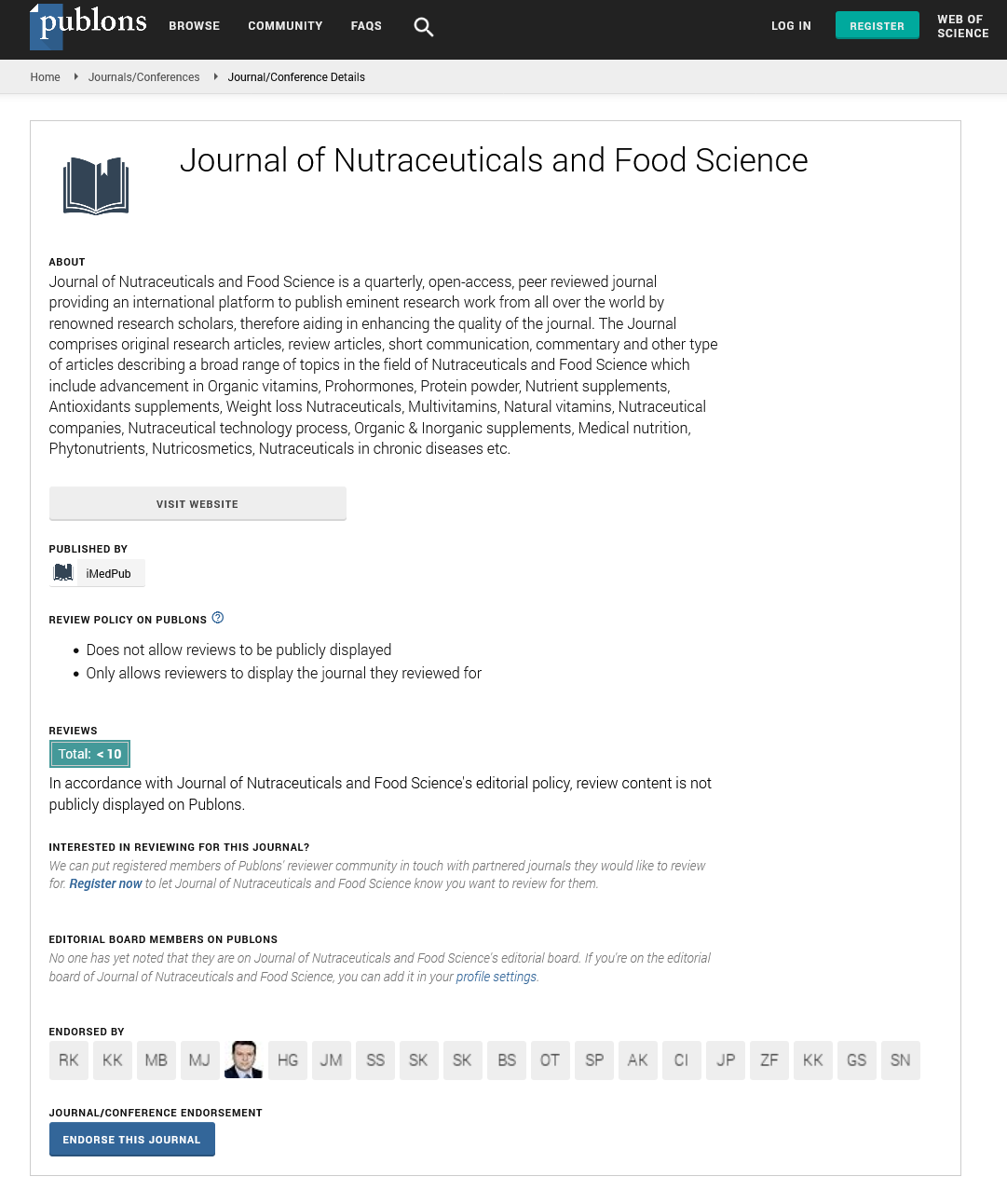

Journal of Nutraceuticals and Food Science peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Publons

- Secret Search Engine Labs

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences