Abstract

Implications of thermal processing on bitterness development in custard apple (Annona squamosa L) fruit pulp: Biochemical and sensory characteristics

Custard apple has a sweet, granular pulp with pleasant flavor. Several constraints exist in industrial processing of custard apple, including enzymatic browning and development of bitterness on heating. Preserving the pulp using conventional method i.e., heat, is practically impossible. This presentation will define reasons for development of bitterness in the pulp on thermal processing and effect of enzymatic clarification of fruit pulp on bitterness. Extraction and characterization of free, bound and esterified phenolics of both fresh and heated pulp were analyzed by UPLC-ESI-MSMS. There was an increase in both free and bound phenolics on heating. Particularly, the precursor ion at m/z 277 was found to increase ~6 folds and tentatively identified as p-decycloxybenzoic acid (PDBA). The contribution of this compound to sensory parameters is still unclear. Further, partially purified fresh and heated tannin fractions were subjected to High Resolution Mass Spectrometry (HRMS). In heated sample, a new precursor ion m/z 139 (M+H) was found at a very high intensity, with fragment ion at m/z 121, which was probably formed by the loss of a water molecule M+H-H2O [M+1-18]. Based on the mass to charge ratio and the fragmentation pattern, m/z 139 was tentatively identified as p-hydroxybenzoic acid (PHB), which is well known to have an acidic and bitter taste. Hence, the perceived bitterness in custard apple pulp on thermal processing is probably due to the synergistic effect of phenolic acids, flavanols and certain low molecular weight compounds formed by heat-induced chemical reactions. Enzymatic clarification of the fruit pulp prevented development of bitterness considerably. This was substantiated with data, as revealed and discussed through HRMS, HPLC, FTIR and sensory analysis in detail.

Author(s):

Revathy Baskaran

Abstract | Full-Text | PDF

Share this

Google scholar citation report

Citations : 393

Journal of Nutraceuticals and Food Science received 393 citations as per google scholar report

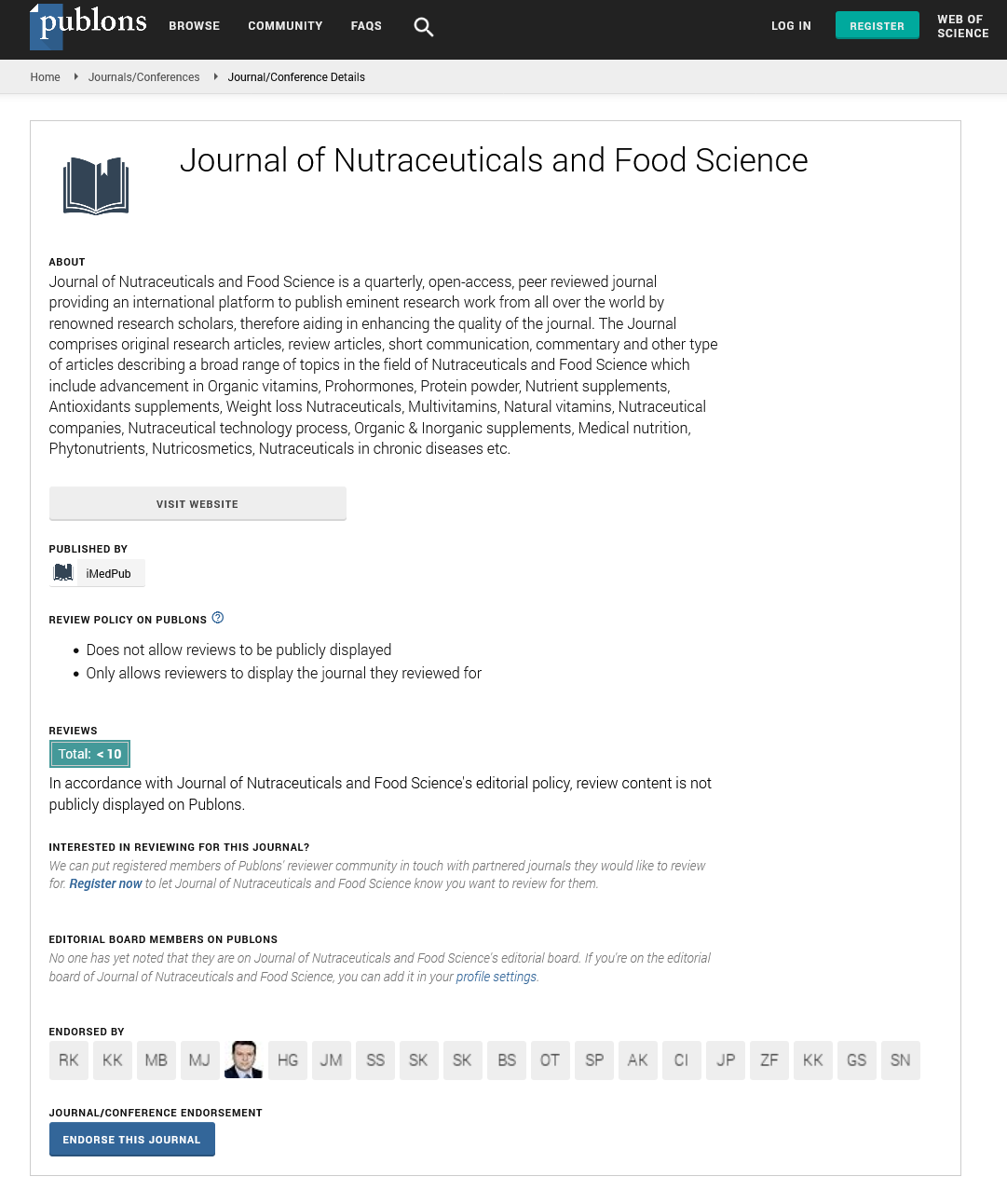

Journal of Nutraceuticals and Food Science peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Publons

- Secret Search Engine Labs

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences