Abstract

APPLICATION OF CENTRAL COMPOSITE DESIGN IN VIRGIN COCONUT OIL EXTRACTION BY INDUCED FERMENTATION

Coconut oil has been described as “the healthiest oil on earth” due to the fact that it composed predominantly of medium chain fatty acids (MCFA) which help to lower the risk of heart disease. In this study, a central composite design (CCD) of response surface methodology (RSM) consisting three factors (Inoculation time, inoculation temperature and inoculum volume) was employed to study the optimum process variables for virgin coconut oil extraction by induced fermentation. Moisture content (MC), saponification value (SV), unsaponifiable matter (UM), free fatty acid (FFA), total phenolic compound (TP), peroxide value (PV) and iodine value (IV) were evaluated as responses. A maximum oil yield of 70% was obtained. Results showed that process variables had significant effect on the responses. The optimum inoculation time, inoculation temperature and inoculum volume with the highest desirability index of 68.2% (0.682) was at 72 h, 60 oC and 5% respectively. Based on 68.2% desirability index, the optimum virgin coconut oil yield, MC, SV, UM, FFA, TP, PV and IV were estimated at 71.88%, 0.12%, 264.81 mg/g, 1.80%, 1.00 mg/g, 6.85 mg/g, 12.81 Eq/kg, and 10.43 mg/g respectively

Author(s):

Edem, V. E

Abstract | Full-Text | PDF

Share this

Google scholar citation report

Citations : 393

Journal of Nutraceuticals and Food Science received 393 citations as per google scholar report

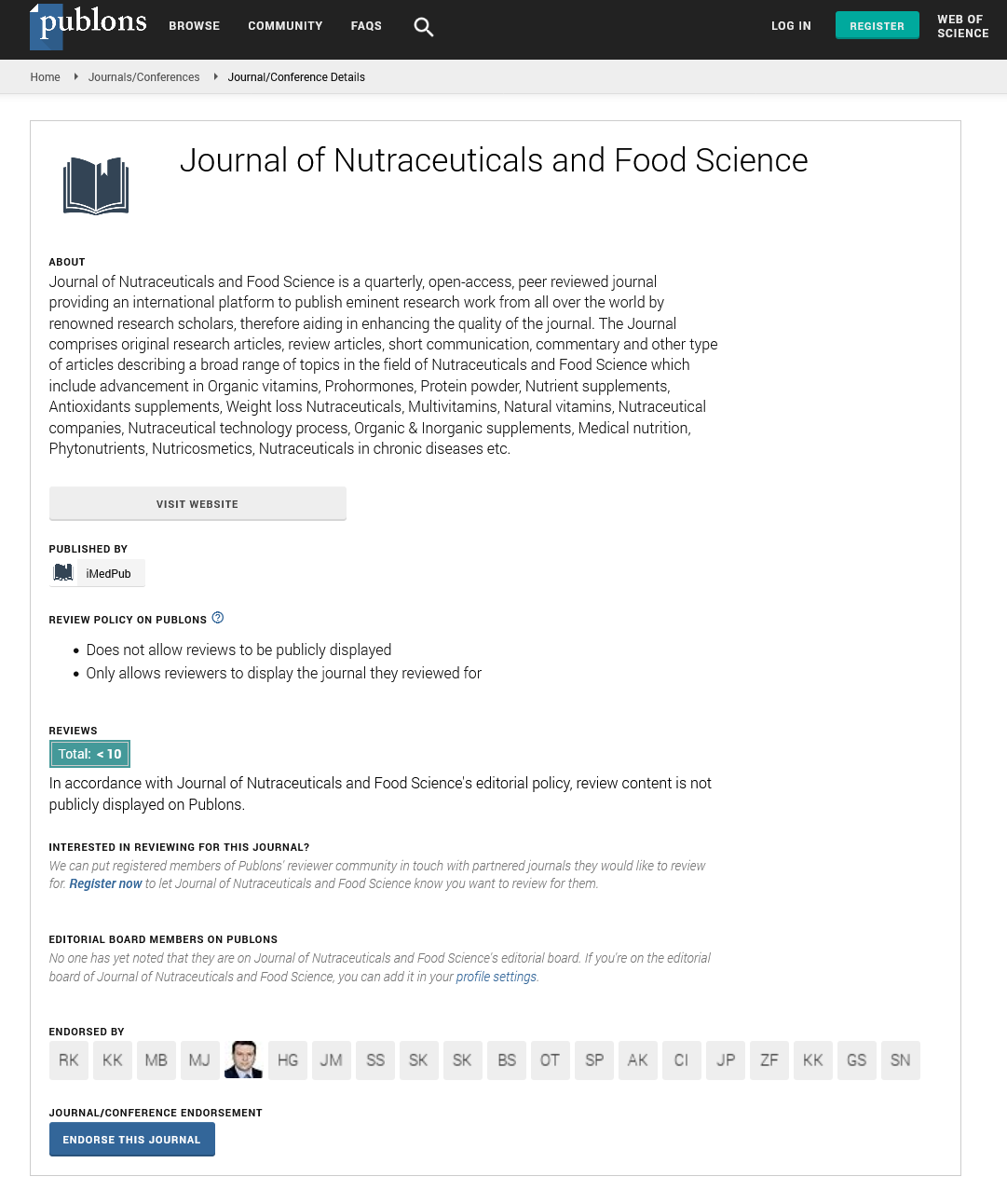

Journal of Nutraceuticals and Food Science peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Publons

- Secret Search Engine Labs

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences