Abstract

A new generation of extruded snacks with the addition of broccoli

There is a growing market for extruded sweet or savory snacks. At the same time, there is a strong focus on the possibility to save water and energy in the food production sector The addition of pulp from fresh vegetables is not only for the development of new types of products, but also allows significantly to reduce the consumption of water and energy during processing what is the result of omitting the drying step. The aim of this work was to investigate the influence of fresh broccoli addition on the extrusion-cooking process of snack pellets. Extrusion-cooking process was performed using the Polish prototype singlescrew extruder-cooker Zamak Mercator type EXP-45-32. Determination of relevant recipe mixtures based on potato or cereal raw materials and the use of fresh broccoli addition in various amount allowed to obtain high-quality snack pellets. The processing efficiency, specific mechanical energy, expansion ratio, bulk density, colour and texture profile were determined. The screw rotation speed had significant effect on processing efficiency, and the interactions between content of broccoli additives and screw speed had significant effect on processing efficiency, physical properties and texture of snack products.

These results are part of the research project LIDER/29/0158/L-10/18/NCBR/2019 entitled “Development of a Comprehensive Technology of Obtaining High-Quality Extruded Snacks Based on Minimally Processed Vegetable and Animal Raw Materials”.

Author(s): Tomasz Oniszczuk

Abstract | Full-Text | PDF

Share this

Google scholar citation report

Citations : 393

Journal of Nutraceuticals and Food Science received 393 citations as per google scholar report

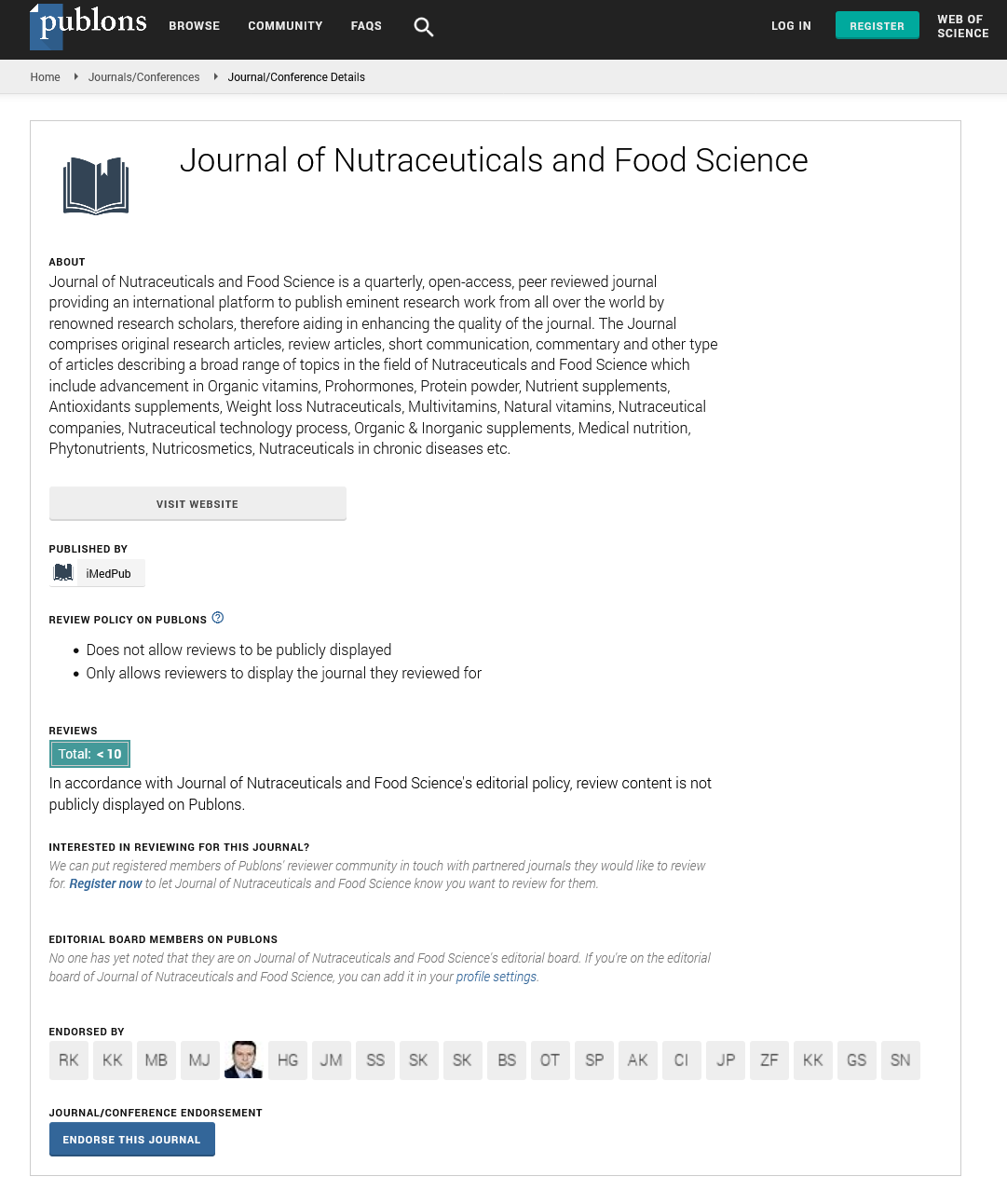

Journal of Nutraceuticals and Food Science peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Publons

- Secret Search Engine Labs

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences